Driver Card

Showing all 10 results

-

Driver Card

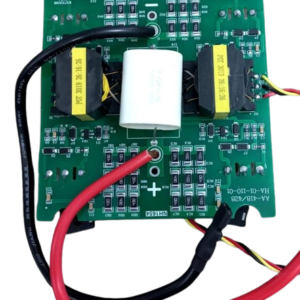

Single-PCB-4 IGBT-4 DIODE-Card

The Single-PCB-4 IGBT-4 DIODE-Card streamlines welding machine circuitry by integrating four Insulated Gate Bipolar Transistors (IGBTs) and four diodes onto a single printed circuit board (PCB). This compact design enhances efficiency, control, and thermal management while ensuring reliable performance in welding applications.

Features

- Integration: Combines four Insulated Gate Bipolar Transistors (IGBTs) and four diodes on a single PCB.

- Compact Design: Space-saving layout optimizes circuitry for efficient performance.

- Enhanced Efficiency: Streamlined configuration improves energy utilization and thermal management.

- Reliable Performance: Ensures consistent and stable operation in welding applications.

- Simplified Circuitry: Reduces complexity and enhances control for smoother welding processes.

- Thermal Management: Efficient design dissipates heat effectively to maintain component integrity.

- Versatile Compatibility: Suitable for a wide range of welding machine configurations and applications.

Applications

- Controls power delivery in welding machines

- Facilitates switching of electrical currents through IGBTs and diodes

- Enables precise regulation of welding parameters such as current, voltage, and duty cycle

- Ensures stable and reliable operation of welding equipment

- Suitable for various welding processes including stick welding, MIG welding, and TIG welding

SKU: n/a -

Driver Card

MMA-400-TOP Card (Three Phase)

The MMA 400 TOP Card is a critical component specifically designed for integration into three-phase arc welding machines, catering to industrial applications where high current output and precision control are essential. This specialized control and regulation unit serves as the central hub for managing and optimizing the welding process, ensuring seamless operation in a variety of demanding environments.

Its advanced design incorporates cutting-edge technology, such as IGBT (Insulated Gate Bipolar Transistor) modules, which enable efficient energy management. This technology ensures the card can handle high-current outputs with minimal energy loss, providing stable arc performance and consistent weld quality even during prolonged operations. The card’s ability to precisely regulate welding parameters, such as current and voltage, makes it indispensable for tasks requiring accuracy and repeatability.

The MMA 400 TOP Card is also engineered for efficiency and reliability. Its robust construction allows it to endure the harsh conditions of industrial environments, including exposure to heat, dust, and vibrations. The inclusion of comprehensive safety features, such as protection against overcurrent, short circuits, and overheating, ensures not only the longevity of the welding equipment but also the safety of the operator.

In high-demand settings like construction, shipbuilding, manufacturing, and automotive repair, the card’s capability to maintain performance under pressure makes it an essential component. With adjustable parameters and compatibility with various machine setups, the MMA 400 TOP Card offers versatility, making it suitable for a wide range of welding applications.

This combination of precision, durability, and advanced safety mechanisms underscores the card’s role as an integral part of heavy-duty industrial welding operations. It enables manufacturers and welders to achieve reliable, high-quality results, meeting the rigorous demands of modern industrial processes.

Features

- Three-Phase Power Support: Efficiently operates with three-phase power supply for enhanced stability and performance.

- High Current Capacity: Handles output currents up to 400A, suitable for heavy-duty welding applications.

- IGBT Technology: Utilizes advanced IGBT modules for efficient power conversion and minimal energy loss.

- Precise Control: Offers accurate regulation of welding current and voltage for stable arcs and consistent weld quality.

- Built-In Protection: Includes safeguards against overcurrent, short circuits, overheating, and overvoltage, ensuring safety and reliability.

- Durable Construction: Designed to withstand harsh industrial environments, including exposure to heat, dust, and mechanical stress.

- Thermal Management: Equipped with efficient cooling mechanisms to prevent overheating during extended use.

- User Configurability: Adjustable parameters for different welding tasks and machine setups.

- Compact and Robust Design: Space-efficient and rugged, ensuring long-term performance even in challenging conditions.

Applications

SKU: n/a -

Driver Card

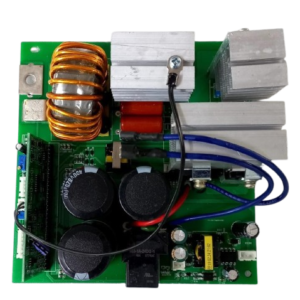

40T120-IGBT-Card

The 40T120 IGBT card in welding machines offers efficient power control, fast switching, and thermal management, ensuring stable and high-performance operation. It’s essential for modern inverter welders. Regular maintenance includes inspecting for damage, ensuring proper cooling, and updating firmware.

Features

- Regulates power flow for precise welding

- Ensures stability and reliability during operations

- Suitable for industrial applications

Applications

- Used in welding machines for controlling power output

- Commonly employed in industrial welding processes

SKU: n/a -

Driver Card

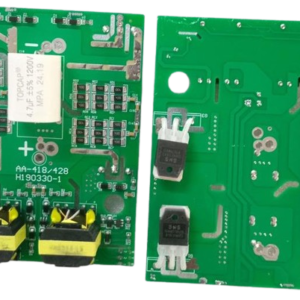

Single-PCB-2 IGBT-2 DIODE-Card

Features

- Dual IGBTs and diodes for efficient power control

- Compact single PCB design for space-saving installation

- Designed for stable and reliable welding operations

- Provides precise current regulation for consistent weld quality

Applications

- Used in welding machines for controlling power delivery to the welding circuit

- Ideal for various welding processes such as MIG, TIG, and Stick welding

SKU: n/a -

Driver Card

18:18 Driver Card

The “18:18 Driver Card” is an essential component used in welding machines. It controls the operation of the welding process by regulating the electrical signals sent to the welding apparatus. This card ensures precise control over the welding parameters, such as voltage, current, and timing, leading to consistent and high-quality welds. With its reliable performance and efficient design, the 18:18 Driver Card plays a crucial role in optimizing welding operations for various applications, including fabrication, construction, automotive repair, and metalworking industries.

Features

- Precise Control: Regulates welding parameters such as voltage and current with accuracy, ensuring consistent weld quality.

- Robust Design: Built to withstand the demanding conditions of industrial welding environments, ensuring durability and reliability.

- Compatibility: Compatible with a wide range of welding machines, offering versatility in application.

- Integrated Protection: Includes protection features to safeguard against overvoltage, overcurrent, and short circuits, enhancing operational safety.

- User-Friendly Interface: User-friendly controls and interface make it easy to adjust settings and monitor welding parameters.

- Compact Size: Compact design allows for easy integration into welding machine systems without occupying excessive space.

Applications

- Industrial Welding: Used in various industrial welding applications such as fabrication, construction, shipbuilding, and metalworking.

- Automotive Repair: Employed in automotive repair shops for welding tasks related to vehicle bodywork and component fabrication.

- Metal Fabrication: Utilized in metal fabrication workshops for welding tasks involving steel, aluminum, and other metals.

- Maintenance and Repair: Applied in maintenance and repair operations across diverse industries for welding tasks ranging from small repairs to large-scale fabrication projects.

SKU: n/a -

Driver Card

15:15 Driver Card

The “15:15 Driver Card” likely refers to a component used in welding machines, specifically for controlling certain aspects of the welding process. Without further details, it’s challenging to provide specific information about this card. However, typically, a driver card in a welding machine controls various functions such as voltage regulation, current modulation, and possibly timing for welding operations.

Features

- Voltage regulation for consistent welding output.

- Current modulation to adjust welding intensity.

- Timing control for precise welding operations.

- Protection features to safeguard against overheating or electrical faults.

Applications

- Used in various types of welding machines, including MIG, TIG, and ARC welders.

- Suitable for industrial welding applications, automotive repair, metal fabrication, and more.

SKU: n/a -

Driver Card

16:8 Big Driver Card

The “16:8 Driver Card” is an essential component utilized in welding machines to regulate and control various parameters during the welding process. It is responsible for managing voltage and current levels, controlling timing parameters, and ensuring the overall stability and efficiency of the welding operation.

Features

- Voltage Regulation: Ensures precise control over the voltage supplied to the welding circuit, maintaining consistency and stability during welding.

- Current Control: Regulates the flow of current through the welding circuit, allowing for adjustments to welding intensity as required.

- Timing Adjustment: Enables operators to control timing parameters, such as the duration of the welding cycle, for optimal results.

- Protection Mechanisms: Incorporates built-in features like overcurrent and overvoltage protection to safeguard welding equipment and ensure operator safety.

- Interface Options: May include interfaces for communication with external devices or control systems, facilitating integration with automation systems and enabling remote monitoring and control functionalities.

Applications

- Manual Welding: Used in manual welding applications where operators have direct control over the welding process.

- Automated Welding: Integrated into automated welding systems for precise control and monitoring of welding parameters.

- Industrial Applications: Employed across various industries, including automotive, construction, manufacturing, and fabrication, for both production and repair/maintenance tasks.

- Versatility: Suitable for a wide range of welding processes, including MIG/MAG, TIG, stick welding, and more.

SKU: n/a -

Driver Card

16:8 Small Driver Card

The “16:8 Driver Card” is an essential component utilized in welding machines to regulate and control various parameters during the welding process. It is responsible for managing voltage and current levels, controlling timing parameters, and ensuring the overall stability and efficiency of the welding operation.

Features

- Voltage Regulation: Ensures precise control over the voltage supplied to the welding circuit, maintaining consistency and stability during welding.

- Current Control: Regulates the flow of current through the welding circuit, allowing for adjustments to welding intensity as required.

- Timing Adjustment: Enables operators to control timing parameters, such as the duration of the welding cycle, for optimal results.

- Protection Mechanisms: Incorporates built-in features like overcurrent and overvoltage protection to safeguard welding equipment and ensure operator safety.

- Interface Options: May include interfaces for communication with external devices or control systems, facilitating integration with automation systems and enabling remote monitoring and control functionalities.

Applications

- Manual Welding: Used in manual welding applications where operators have direct control over the welding process.

- Automated Welding: Integrated into automated welding systems for precise control and monitoring of welding parameters.

- Industrial Applications: Employed across various industries, including automotive, construction, manufacturing, and fabrication, for both production and repair/maintenance tasks.

- Versatility: Suitable for a wide range of welding processes, including MIG/MAG, TIG, stick welding, and more.

SKU: n/a