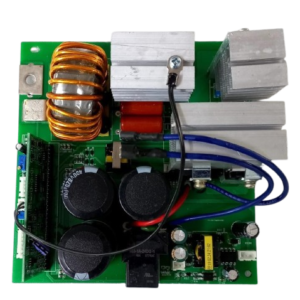

The “15:15 Driver Card” is an essential component found in welding machines, tasked with managing critical aspects of the welding process. Its primary role revolves around controlling and regulating crucial parameters to ensure optimal performance and precise operation during welding tasks. Overall, the “15:15 Driver Card” plays a vital role in ensuring the efficiency, accuracy, and safety of welding operations. Its capabilities and features contribute to achieving high-quality welds while providing operators with the flexibility and control needed to meet diverse welding requirements.

15:15 Driver Card

19 in stock

The “15:15 Driver Card” likely refers to a component used in welding machines, specifically for controlling certain aspects of the welding process. Without further details, it’s challenging to provide specific information about this card. However, typically, a driver card in a welding machine controls various functions such as voltage regulation, current modulation, and possibly timing for welding operations.

Features

- Voltage regulation for consistent welding output.

- Current modulation to adjust welding intensity.

- Timing control for precise welding operations.

- Protection features to safeguard against overheating or electrical faults.

Applications

- Used in various types of welding machines, including MIG, TIG, and ARC welders.

- Suitable for industrial welding applications, automotive repair, metal fabrication, and more.

₹360.00 ₹367.00

19 in stock

You may also like…

-

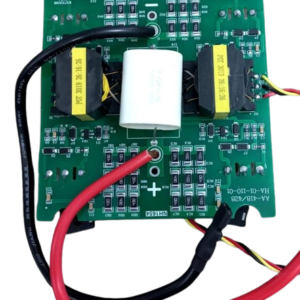

Driver Card

Single-PCB-2 IGBT-2 DIODE-Card

Features

- Dual IGBTs and diodes for efficient power control

- Compact single PCB design for space-saving installation

- Designed for stable and reliable welding operations

- Provides precise current regulation for consistent weld quality

Applications

- Used in welding machines for controlling power delivery to the welding circuit

- Ideal for various welding processes such as MIG, TIG, and Stick welding

SKU: n/a -

Control Card

200-MOSFET-Control Card(With Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

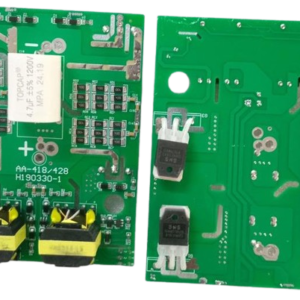

Control Card

MMA 200 TOP Card (Single Phase)-18N50-MOSFET-PCB-Control Card

The “18n50 MOSFET PCB Control Card” is a crucial component utilized in welding machines to regulate and control the power delivery for welding operations. This card integrates MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), which are semiconductor devices known for their high switching speeds and efficiency. The card plays a key role in maintaining precise control over the welding process, ensuring stable and consistent output currents and voltages. It enhances the performance and reliability of welding machines, contributing to smooth and efficient welding operations.

Features

- MOSFET Integration: Incorporates MOSFETs for efficient power switching and control.

- High-Speed Operation: Offers rapid switching capabilities for precise control over power flow.

- Stable Performance: Ensures stable and consistent output currents and voltages during welding operations.

- Reliable Operation: Designed for reliable performance in demanding industrial environments.

- Compatibility: Compatible with various types of welding machines and systems.

- Compact Design: Compact PCB design for easy integration into welding machine assemblies.

Applications

- Welding Machines: Used in various types of welding machines, including arc welders, MIG welders, and TIG welders.

- Industrial Fabrication: Employed in industrial fabrication processes for joining metal components.

- Automotive Industry: Used in welding applications within the automotive manufacturing sector.

- Construction Projects: Applied in construction projects for structural welding tasks.

- Repair and Maintenance: Utilized in repair workshops and maintenance facilities for welding equipment servicing.

- Metalworking Operations: Used in metalworking operations for creating strong and durable weld joints.

SKU: n/a

There are no reviews yet.