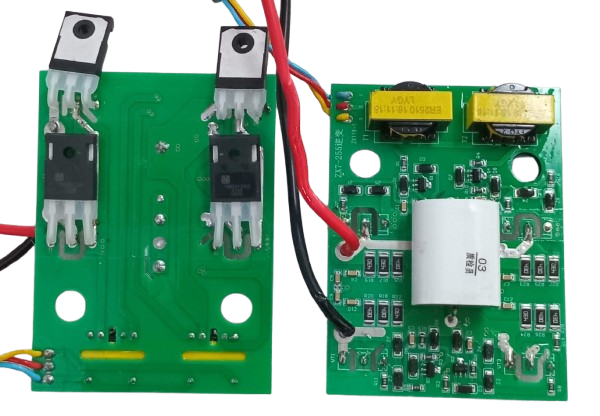

The 25N120 IGBT (Insulated Gate Bipolar Transistor) card is an essential component utilized in welding machines for power control and management. This card plays a crucial role in regulating the flow of electricity to ensure smooth and efficient welding operations. It helps in controlling the current and voltage levels, thereby maintaining stability and precision during the welding process. The 25N120 IGBT card offers high reliability, durability, and performance, making it a vital part of welding equipment used in various industrial applications.

25N120-IGBT-Card

19 in stock

The 25N120 IGBT card is a key component in welding machines, regulating power flow for precise and efficient welding. It ensures stability and reliability during operations, crucial for industrial applications.

Features

- Regulates power flow for precise welding

- Ensures stability and reliability during operations

- Suitable for industrial applications

Applications

- Used in welding machines for controlling power output

- Commonly employed in industrial welding processes

₹1,000.00 ₹1,070.00

19 in stock

| Attribute | Value |

|---|---|

| Material | Mild Steel |

| Usage/Application | Electronics |

| Brand | IGBT WELDING MACHINE SINGLE TWO PHASE |

| Model/Type | 25N120 IGBT |

| Output Current | 0-100 (A) |

| Packaging Type | Box |

Based on 0 reviews

Be the first to review “25N120-IGBT-Card”

You may also like…

-

Control Card

MMA 200 TOP Card (Single Phase)-18N50-MOSFET-PCB-Control Card

The “18n50 MOSFET PCB Control Card” is a crucial component utilized in welding machines to regulate and control the power delivery for welding operations. This card integrates MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), which are semiconductor devices known for their high switching speeds and efficiency. The card plays a key role in maintaining precise control over the welding process, ensuring stable and consistent output currents and voltages. It enhances the performance and reliability of welding machines, contributing to smooth and efficient welding operations.

Features

- MOSFET Integration: Incorporates MOSFETs for efficient power switching and control.

- High-Speed Operation: Offers rapid switching capabilities for precise control over power flow.

- Stable Performance: Ensures stable and consistent output currents and voltages during welding operations.

- Reliable Operation: Designed for reliable performance in demanding industrial environments.

- Compatibility: Compatible with various types of welding machines and systems.

- Compact Design: Compact PCB design for easy integration into welding machine assemblies.

Applications

- Welding Machines: Used in various types of welding machines, including arc welders, MIG welders, and TIG welders.

- Industrial Fabrication: Employed in industrial fabrication processes for joining metal components.

- Automotive Industry: Used in welding applications within the automotive manufacturing sector.

- Construction Projects: Applied in construction projects for structural welding tasks.

- Repair and Maintenance: Utilized in repair workshops and maintenance facilities for welding equipment servicing.

- Metalworking Operations: Used in metalworking operations for creating strong and durable weld joints.

SKU: n/a -

Driver Card

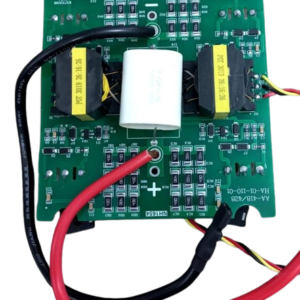

18:18 Driver Card

The “18:18 Driver Card” is an essential component used in welding machines. It controls the operation of the welding process by regulating the electrical signals sent to the welding apparatus. This card ensures precise control over the welding parameters, such as voltage, current, and timing, leading to consistent and high-quality welds. With its reliable performance and efficient design, the 18:18 Driver Card plays a crucial role in optimizing welding operations for various applications, including fabrication, construction, automotive repair, and metalworking industries.

Features

- Precise Control: Regulates welding parameters such as voltage and current with accuracy, ensuring consistent weld quality.

- Robust Design: Built to withstand the demanding conditions of industrial welding environments, ensuring durability and reliability.

- Compatibility: Compatible with a wide range of welding machines, offering versatility in application.

- Integrated Protection: Includes protection features to safeguard against overvoltage, overcurrent, and short circuits, enhancing operational safety.

- User-Friendly Interface: User-friendly controls and interface make it easy to adjust settings and monitor welding parameters.

- Compact Size: Compact design allows for easy integration into welding machine systems without occupying excessive space.

Applications

- Industrial Welding: Used in various industrial welding applications such as fabrication, construction, shipbuilding, and metalworking.

- Automotive Repair: Employed in automotive repair shops for welding tasks related to vehicle bodywork and component fabrication.

- Metal Fabrication: Utilized in metal fabrication workshops for welding tasks involving steel, aluminum, and other metals.

- Maintenance and Repair: Applied in maintenance and repair operations across diverse industries for welding tasks ranging from small repairs to large-scale fabrication projects.

SKU: n/a -

Control Card

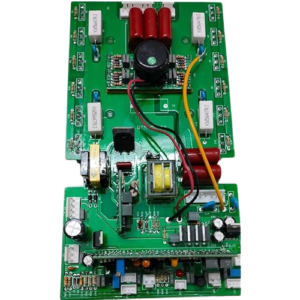

MMA 200 TOP Card (Single Phase)-23N50-MOSFET-PCB-Control Card

The 23N50 MOSFET PCB Control Card used in welding machines is a critical component responsible for regulating and controlling the flow of power through the MOSFETs in the welding equipment. This card ensures precise modulation of electrical currents, enabling efficient welding processes with optimal performance and reliability.

Features

- Integration with MOSFETs for efficient power regulation and control.

- Precision modulation of output current and voltage for consistent weld quality.

- Compatibility with various welding processes and materials.

- Incorporation of protective features such as overcurrent and overvoltage protection.

- Robust construction for durability and reliability in industrial environments.

- Compact design for easy integration into welding machine systems.

- User-friendly interface for intuitive operation and adjustment of welding parameters.

Applications

- Used in welding machines for precise control of power modulation during welding operations.

- Interfaces with MOSFETs to regulate output current and voltage, ensuring optimal performance and weld quality.

- Enables adjustment of electrical parameters to suit various welding processes and materials.

SKU: n/a

There are no reviews yet.