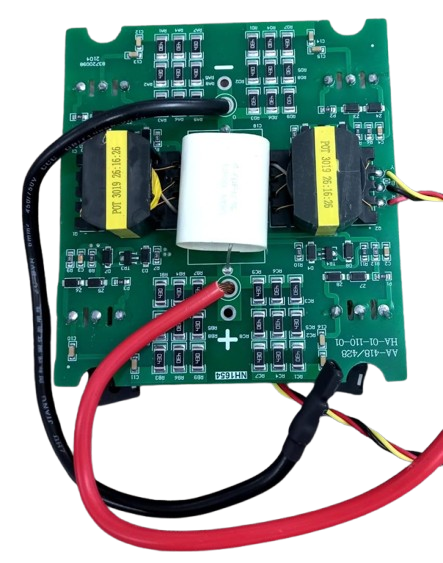

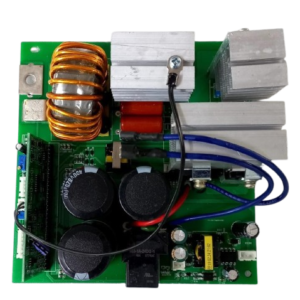

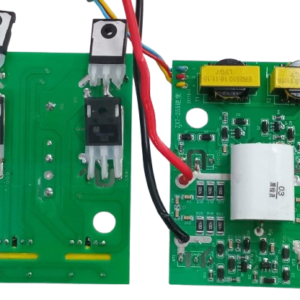

The MMA 400 TOP Card is a critical component specifically designed for integration into three-phase arc welding machines, catering to industrial applications where high current output and precision control are essential. This specialized control and regulation unit serves as the central hub for managing and optimizing the welding process, ensuring seamless operation in a variety of demanding environments.

Its advanced design incorporates cutting-edge technology, such as IGBT (Insulated Gate Bipolar Transistor) modules, which enable efficient energy management. This technology ensures the card can handle high-current outputs with minimal energy loss, providing stable arc performance and consistent weld quality even during prolonged operations. The card’s ability to precisely regulate welding parameters, such as current and voltage, makes it indispensable for tasks requiring accuracy and repeatability.

The MMA 400 TOP Card is also engineered for efficiency and reliability. Its robust construction allows it to endure the harsh conditions of industrial environments, including exposure to heat, dust, and vibrations. The inclusion of comprehensive safety features, such as protection against overcurrent, short circuits, and overheating, ensures not only the longevity of the welding equipment but also the safety of the operator.

In high-demand settings like construction, shipbuilding, manufacturing, and automotive repair, the card’s capability to maintain performance under pressure makes it an essential component. With adjustable parameters and compatibility with various machine setups, the MMA 400 TOP Card offers versatility, making it suitable for a wide range of welding applications.

This combination of precision, durability, and advanced safety mechanisms underscores the card’s role as an integral part of heavy-duty industrial welding operations. It enables manufacturers and welders to achieve reliable, high-quality results, meeting the rigorous demands of modern industrial processes.

Features

- Three-Phase Power Support: Efficiently operates with three-phase power supply for enhanced stability and performance.

- High Current Capacity: Handles output currents up to 400A, suitable for heavy-duty welding applications.

- IGBT Technology: Utilizes advanced IGBT modules for efficient power conversion and minimal energy loss.

- Precise Control: Offers accurate regulation of welding current and voltage for stable arcs and consistent weld quality.

- Built-In Protection: Includes safeguards against overcurrent, short circuits, overheating, and overvoltage, ensuring safety and reliability.

- Durable Construction: Designed to withstand harsh industrial environments, including exposure to heat, dust, and mechanical stress.

- Thermal Management: Equipped with efficient cooling mechanisms to prevent overheating during extended use.

- User Configurability: Adjustable parameters for different welding tasks and machine setups.

- Compact and Robust Design: Space-efficient and rugged, ensuring long-term performance even in challenging conditions.

Applications

- Industrial Fabrication: Used in the manufacturing of heavy machinery, industrial equipment, and large-scale metal structures.

- Construction: Ideal for welding structural steel and other critical components in construction projects.

- Automotive Industry: Applied in welding tasks like vehicle body repairs and fabrication of automotive parts.

- Shipbuilding: Suitable for welding large metal sections and components in marine applications.

- Pipeline Welding: Handles high-current welding for pipelines in oil, gas, and utility industries.

- Custom Welding Workshops: Perfect for specialized and custom welding operations in fabrication and repair workshops.

- Energy Sector: Supports welding in power plants, refineries, and other energy-related infrastructure projects.

- Repair and Maintenance: Essential for industrial equipment repairs, machinery maintenance, and structural welding in maintenance workshops.

There are no reviews yet.