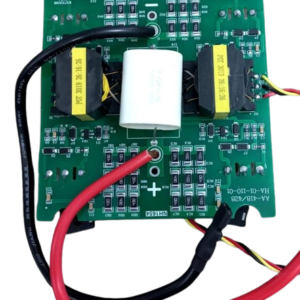

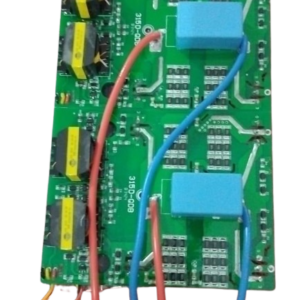

The Bottom-Card Power Supply Card is a critical and foundational component in arc welding machines, designed to provide stable and reliable power delivery while protecting sensitive electronic components from electrical disturbances. It plays a vital role in maintaining the overall functionality and performance of the welding machine by regulating the power supply, distributing it efficiently to various subsystems, and ensuring consistent operation under demanding industrial and professional conditions.

This card serves as the backbone of the welding machine’s power management system, converting input voltage into regulated outputs required for different components, such as control circuits, driver boards, display modules, and sensors. By ensuring stable voltage and current levels, even in the face of fluctuating input power or environmental conditions, it protects critical parts like MOSFETs, IGBTs, and microcontrollers from potential damage caused by surges, undervoltage, or short circuits.

In addition to its protective capabilities, the Bottom-Card Power Supply Card plays a key role in enhancing the machine’s reliability. A stable power supply ensures the welding arc remains smooth and consistent, which is essential for achieving high-quality welds with minimal spatter and optimal penetration. This reliability is particularly important for industrial welding applications, where prolonged duty cycles and continuous operation are common. The card’s ability to handle such heavy-duty requirements while ensuring consistent performance makes it indispensable for professional welders and industrial environments.

The Bottom-Card Power Supply Card also contributes to the overall efficiency of the welding machine. By utilizing advanced power conversion and distribution technologies, it minimizes energy losses and heat generation, reducing operating costs and improving the machine’s energy efficiency. Its robust construction and use of high-quality components ensure durability and long-term performance, even in harsh conditions, such as high temperatures, dust, and vibrations.

To maintain optimal performance and longevity, proper maintenance of the Bottom-Card Power Supply Card is essential. Regular inspection for signs of wear, overheating, or damage, as well as cleaning to prevent the accumulation of dust and debris, can help avoid potential issues. Additionally, ensuring secure connections and replacing damaged components promptly are key steps in preserving the card’s functionality. Troubleshooting any anomalies, such as inconsistent power delivery or erratic machine behavior, should be addressed immediately to prevent further complications.

In conclusion, the Bottom-Card Power Supply Card is a vital component of arc welding machines, ensuring stable power delivery, protecting sensitive parts, and enhancing the machine’s reliability, welding quality, and operational efficiency. Its importance cannot be overstated, as it underpins the consistent performance of welding machines in both industrial and professional settings. With proper maintenance and timely troubleshooting, the Bottom-Card Power Supply Card ensures that the welding machine operates at its peak potential, meeting the demands of even the most challenging welding tasks.

There are no reviews yet.