The 200 Top Blank Card is a generic control platform used in various arc welding machines. It’s referred to as a “blank card” because it typically comes without pre-programmed functionality—allowing manufacturers, service centers, or engineers to customize it according to the specific needs of a welding machine.

200-Top-Blank-Card

25 in stock

The 200 Top Blank Card is a versatile and adaptable control platform commonly used in a wide range of arc welding machines, particularly in models like ARC 200, TIG 200, and other inverter-based welding systems. It serves as the central brain of the welding machine, responsible for coordinating various functions such as current regulation, voltage monitoring, protection control, and user interface.

Features

-

Universal Design

-

Custom Firmware Support

-

Multiple Input/Output Ports

-

Protection Functionality (Programmable)

-

Compact PCB Layout

-

Cost-Effective and Service-Friendly

-

Flexible Voltage Operation

Applications

-

ARC Welding Machines (e.g., ARC 200)

-

TIG Welding Machines (TIG 200, Lift TIG)

-

Welding Machine Repair and Servicing

-

R&D and Custom Machine Development

-

Training and Educational Kits

-

Prototype Welding Projects.

₹1,700.00 ₹1,750.00

25 in stock

You may also like…

-

Control Card

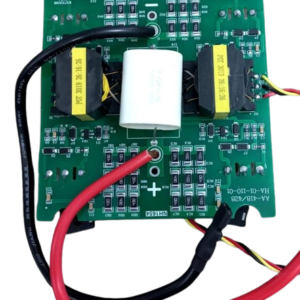

200-MOSFET-Control Card(With Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Driver Card

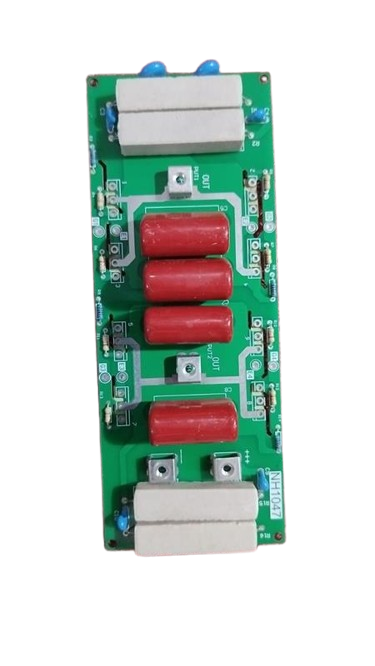

16:8 Big Driver Card

The “16:8 Driver Card” is an essential component utilized in welding machines to regulate and control various parameters during the welding process. It is responsible for managing voltage and current levels, controlling timing parameters, and ensuring the overall stability and efficiency of the welding operation.

Features

- Voltage Regulation: Ensures precise control over the voltage supplied to the welding circuit, maintaining consistency and stability during welding.

- Current Control: Regulates the flow of current through the welding circuit, allowing for adjustments to welding intensity as required.

- Timing Adjustment: Enables operators to control timing parameters, such as the duration of the welding cycle, for optimal results.

- Protection Mechanisms: Incorporates built-in features like overcurrent and overvoltage protection to safeguard welding equipment and ensure operator safety.

- Interface Options: May include interfaces for communication with external devices or control systems, facilitating integration with automation systems and enabling remote monitoring and control functionalities.

Applications

- Manual Welding: Used in manual welding applications where operators have direct control over the welding process.

- Automated Welding: Integrated into automated welding systems for precise control and monitoring of welding parameters.

- Industrial Applications: Employed across various industries, including automotive, construction, manufacturing, and fabrication, for both production and repair/maintenance tasks.

- Versatility: Suitable for a wide range of welding processes, including MIG/MAG, TIG, stick welding, and more.

SKU: n/a -

Driver Card

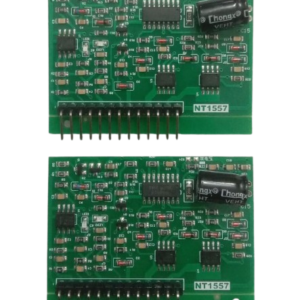

16:8 Small Driver Card

The “16:8 Driver Card” is an essential component utilized in welding machines to regulate and control various parameters during the welding process. It is responsible for managing voltage and current levels, controlling timing parameters, and ensuring the overall stability and efficiency of the welding operation.

Features

- Voltage Regulation: Ensures precise control over the voltage supplied to the welding circuit, maintaining consistency and stability during welding.

- Current Control: Regulates the flow of current through the welding circuit, allowing for adjustments to welding intensity as required.

- Timing Adjustment: Enables operators to control timing parameters, such as the duration of the welding cycle, for optimal results.

- Protection Mechanisms: Incorporates built-in features like overcurrent and overvoltage protection to safeguard welding equipment and ensure operator safety.

- Interface Options: May include interfaces for communication with external devices or control systems, facilitating integration with automation systems and enabling remote monitoring and control functionalities.

Applications

- Manual Welding: Used in manual welding applications where operators have direct control over the welding process.

- Automated Welding: Integrated into automated welding systems for precise control and monitoring of welding parameters.

- Industrial Applications: Employed across various industries, including automotive, construction, manufacturing, and fabrication, for both production and repair/maintenance tasks.

- Versatility: Suitable for a wide range of welding processes, including MIG/MAG, TIG, stick welding, and more.

SKU: n/a

There are no reviews yet.