The 200Amp-1200Volt IGBT module is a critical component in modern welding machines, offering high efficiency, durability, and precise control. Combining the benefits of MOSFETs and bipolar transistors, these modules handle substantial currents and voltages, making them ideal for demanding industrial applications. They enhance welding machine performance by providing efficient power switching, voltage and current regulation, and effective heat management. Widely used in industrial welding, inverter welding machines, and automated welding systems, these IGBT modules ensure superior weld quality, energy savings, and increased productivity.

200Amp-1200Volt

50 in stock

The 200Amp-1200Volt IGBT module is essential in modern welding machines, providing high efficiency, durability, and precise control. These modules handle substantial currents and voltages, making them ideal for industrial applications. They enhance performance through efficient power switching, voltage regulation, and effective heat management, ensuring superior weld quality and increased productivity.

Features

- High Current and Voltage Rating: Capable of handling up to 200Amps and 1200Volts.

- Modular Design: Allows for easy installation, maintenance, and scalability.

- Efficient Power Conversion: Ensures optimal energy conversion for stable welding.

- Reliable Performance: Provides consistent and reliable operation.

- Robust Construction: Built to withstand harsh industrial environments.

- Integrated Protection Mechanisms: Includes overcurrent and overvoltage protection.

Applications

- Industrial Welding: Metal fabrication, construction, and automotive manufacturing.

- Arc Welding Machines: Controls and regulates welding current and voltage.

- Resistance Welding: Joins metal components in manufacturing processes.

- Inverter Welding Systems: Efficient power conversion and control.

- Welding Automation: High-speed and precise welding operations.

- Heavy-duty Welding: Shipbuilding, pipeline construction, and structural steel fabrication.

₹4,550.00 ₹4,650.00

50 in stock

You may also like…

-

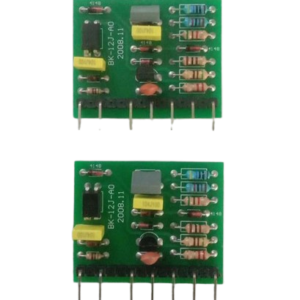

Supply Card

24 Volt Supply Card

A “24V Supply Card” in a welding machine typically refers to a component responsible for providing a stable 24-volt power supply to various parts of the machine. This card ensures consistent power delivery, which is crucial for the proper functioning of electronic components within the welding equipment. It may include features such as overvoltage protection, short-circuit protection, and voltage regulation to maintain a steady voltage output under varying load conditions. The 24V supply card plays a vital role in powering control circuits, interface panels, and other electrical components essential for the welding process.

Features

- Provides a stable 24-volt power supply to welding machine components.

- Incorporates protective features such as overvoltage and short-circuit protection.

- Regulates output voltage to ensure consistency during varying load conditions.

- Designed for reliable and efficient power distribution within the welding equipment.

Applications

- Used in welding machines of various types and sizes.

- Essential for powering control circuits, interface panels, and electronic components.

- Ensures consistent and reliable operation of the welding equipment during welding processes.

- Suitable for industrial applications where stable power supply is crucial for performance and safety.

SKU: n/a -

IGBT Module

75Amp-1200Volt

A 75Amp-1200Volt modular IGBT, often utilized in welding machines, serves as a fundamental component for power conversion and control. With its high current and voltage ratings, it enables efficient energy transfer and regulation within the welding equipment. The modular design allows for easy integration and scalability, enhancing the flexibility and reliability of the welding system.

Features

- High Current and Voltage Rating: Capable of handling up to 75Amps and 1200Volts.

- Modular Design: Allows for easy installation, maintenance, and scalability.

- Efficient Power Conversion: Ensures optimal energy conversion for stable welding.

- Reliable Performance: Provides consistent and reliable operation.

- Robust Construction: Built to withstand harsh industrial environments.

- Integrated Protection Mechanisms: Includes overcurrent and overvoltage protection.

Applications

- Industrial Welding: Metal fabrication, construction, and automotive manufacturing.

- Arc Welding Machines: Controls and regulates welding current and voltage.

- Resistance Welding: Joins metal components in manufacturing processes.

- Inverter Welding Systems: Efficient power conversion and control.

- Welding Automation: High-speed and precise welding operations.

- Heavy-duty Welding: Shipbuilding, pipeline construction, and structural steel fabrication.

SKU: n/a -

Driver Card

18:18 Driver Card

The “18:18 Driver Card” is an essential component used in welding machines. It controls the operation of the welding process by regulating the electrical signals sent to the welding apparatus. This card ensures precise control over the welding parameters, such as voltage, current, and timing, leading to consistent and high-quality welds. With its reliable performance and efficient design, the 18:18 Driver Card plays a crucial role in optimizing welding operations for various applications, including fabrication, construction, automotive repair, and metalworking industries.

Features

- Precise Control: Regulates welding parameters such as voltage and current with accuracy, ensuring consistent weld quality.

- Robust Design: Built to withstand the demanding conditions of industrial welding environments, ensuring durability and reliability.

- Compatibility: Compatible with a wide range of welding machines, offering versatility in application.

- Integrated Protection: Includes protection features to safeguard against overvoltage, overcurrent, and short circuits, enhancing operational safety.

- User-Friendly Interface: User-friendly controls and interface make it easy to adjust settings and monitor welding parameters.

- Compact Size: Compact design allows for easy integration into welding machine systems without occupying excessive space.

Applications

- Industrial Welding: Used in various industrial welding applications such as fabrication, construction, shipbuilding, and metalworking.

- Automotive Repair: Employed in automotive repair shops for welding tasks related to vehicle bodywork and component fabrication.

- Metal Fabrication: Utilized in metal fabrication workshops for welding tasks involving steel, aluminum, and other metals.

- Maintenance and Repair: Applied in maintenance and repair operations across diverse industries for welding tasks ranging from small repairs to large-scale fabrication projects.

SKU: n/a -

Control Card

200-MOSFET-Control Card(With Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a

There are no reviews yet.