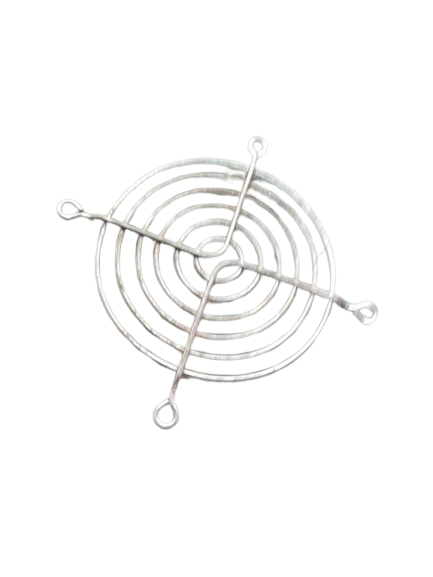

The cooling fan frame is an essential structural component in welding machines, specifically designed to securely hold and protect the cooling fan. Its primary role is to ensure that the fan operates efficiently, directing airflow across critical components inside the machine. By maintaining proper ventilation, the cooling fan frame supports the dissipation of excess heat generated during welding operations.

Welding machines, especially modern inverter-based models, handle high currents and operate for extended periods, which naturally leads to significant heat buildup. Without proper cooling, this heat can damage sensitive electronic parts such as MOSFET or IGBT cards, transformers, rectifiers, and control boards. The cooling fan frame not only keeps the fan in a stable position to optimize airflow but also shields it from external dust, sparks, and mechanical vibrations that could otherwise compromise its performance.

In addition, the durability of the fan frame is critical. Typically made from high-quality metal or heat-resistant plastic, it is designed to withstand the tough conditions of industrial and workshop environments. By ensuring stable cooling performance, the fan frame directly contributes to the longevity, safety, and reliability of the welding machine.

There are no reviews yet.