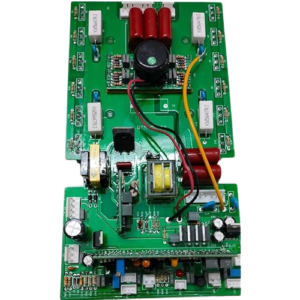

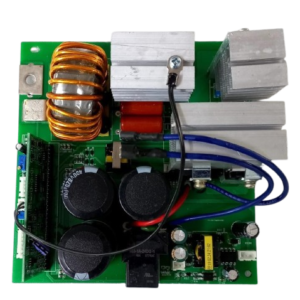

The single PCB control card used in welding machines serves as the central hub for regulating and managing the welding process. It incorporates various control components, including microcontrollers, sensors, and interfaces, onto a single circuit board. This integration streamlines the wiring and assembly process, reducing complexity and potential points of failure.

Through advanced control algorithms, the PCB control card precisely monitors and adjusts parameters such as voltage, current, and timing, ensuring optimal welding performance and consistent weld quality. It provides real-time feedback and adjustments to adapt to changing welding conditions, resulting in reliable and uniform welds across different workpieces.

This control card is versatile and compatible with various types of welding machines, including arc welders, MIG welders, TIG welders, and spot welders. Its compact design and efficient operation make it suitable for both industrial and commercial welding applications. Additionally, its user-friendly interface facilitates easy operation and programming, allowing welders to set parameters and monitor the welding process with ease.

Overall, the single PCB control card offers a reliable, efficient, and user-friendly solution for controlling welding operations, contributing to improved productivity, quality, and efficiency in welding applications.

There are no reviews yet.