Shop

Showing 31–45 of 208 results

-

DC Cooling Fans

4.5 inch-DC Fan

These fans are versatile solutions for air cooling in various industries. Designed to industry standards, they ensure compatibility with different control panel systems. With a sleek design, they not only meet cooling needs but also enhance the aesthetics of electrical panels. Featuring a slim profile, quick mounting, high performance, and optimized grill design, they minimize noise while maximizing airflow.

SKU: n/a -

Control Card

8-IGBT-Card-Blank Card

The 8-IGBT-Card Blank Card plays a vital role in the performance and efficiency of modern arc welding machines. It is specifically designed to control the operation of Insulated Gate Bipolar Transistors (IGBTs), which are at the heart of inverter-based welding technology.

Features

- High-Speed IGBT Driving

- Delivers precise gate drive signals to IGBTs for fast and efficient operation.

- Enables high-frequency switching, ensuring stable arc performance and reduced spatter.

- Integrated Protection Mechanisms

- Safeguards against overcurrent, overvoltage, and thermal stress.

- Enhances durability by protecting critical machine components.

- Compact and Lightweight Design

- Optimized for integration into modern inverter welding machines.

- Contributes to the portability of the welding system.

- Real-Time Feedback and Monitoring

- Continuously tracks welding parameters like current and voltage.

- Provides adaptive control to maintain arc stability in varying conditions.

- Energy Efficiency

- Reduces power losses with optimized IGBT switching.

- Increases overall machine efficiency, reducing energy costs.

- Versatility and Compatibility

- Works with a wide range of welding machine types, including MMA and TIG systems.

- Supports diverse welding materials and applications.

- Enhanced Arc Stability

- Ensures a consistent and steady arc for superior weld quality.

Applications

- Inverter Arc Welding Machines

- Core component of compact and energy-efficient inverter-based welding systems.

- TIG Welding Machines

- Used for precise Tungsten Inert Gas (TIG) welding, ideal for intricate tasks and thin materials.

- MMA Welding Machines

- Suitable for heavy-duty Manual Metal Arc (MMA) welding applications.

- Industrial Automation Systems

- Powers automated welding solutions in industrial assembly lines.

- Repairs and Maintenance Services

- Provides flexibility for welding in repair and maintenance tasks across various metal types.

- Custom Welding Applications

- Adaptable to specialized welding needs in industries like shipbuilding, construction, and manufacturing.

SKU: n/a -

Control Card

25N120-IGBT-Card

The 25N120 IGBT card is a key component in welding machines, regulating power flow for precise and efficient welding. It ensures stability and reliability during operations, crucial for industrial applications.

Features

- Regulates power flow for precise welding

- Ensures stability and reliability during operations

- Suitable for industrial applications

Applications

- Used in welding machines for controlling power output

- Commonly employed in industrial welding processes

SKU: n/a -

Control Card

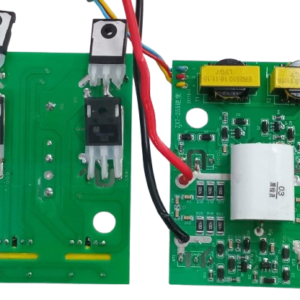

200-MOSFET-Control Card(With Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Control Card

Sakti-Control-Card

The “Sakti-Control-Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 400-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Control Card

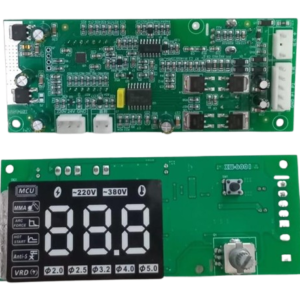

MMA-400-Control-Card/ZX7-Nikko-Control-Card

The “MMA-400-Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 400-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Control Card

Single-PCB-IGBT-IC-Control-Card(25 Pin) (Copy)

The single PCB control card for welding machines is a compact and integrated solution that regulates welding processes with precision. It combines various control components onto a single board, simplifying wiring and assembly. Through advanced algorithms, it monitors and adjusts welding parameters in real-time, ensuring consistent weld quality. Versatile and user-friendly, it’s compatible with different welding types and offers efficient operation for industrial and commercial applications.

Features

- Compact design for space-saving installation.

- High-performance microcontroller for precise control over welding parameters.

- Integrated circuitry for monitoring and regulating voltage, current, and temperature.

- User-friendly interface for easy operation and adjustment of welding settings.

- Built-in safety features to prevent overheating, overloading, and short circuits.

- Compatibility with various welding processes and power sources.

- Robust construction for durability and reliability in industrial environments.

- Flexible connectivity options for interfacing with external devices and peripherals.

- Modular design for easy maintenance and upgradeability.

- Advanced control algorithms for optimized welding performance and efficiency.

Applications

- Welding machines for various welding processes such as arc welding, MIG welding, TIG welding, etc.

- Industrial fabrication and manufacturing processes requiring precise control over welding parameters.

- Automotive and aerospace industries for welding components and structures.

- Construction projects for welding structural steel and other metal components.

- Repair and maintenance workshops for welding repairs on machinery, equipment, and vehicles.

SKU: n/a -

Control Card

SHAKTI-40N120-IGBT-Card

The SHAKTI-40N120-IGBT-Card plays a vital role in the performance and efficiency of modern arc welding machines. It is specifically designed to control the operation of Insulated Gate Bipolar Transistors (IGBTs), which are at the heart of inverter-based welding technology.

Features

- High-Speed IGBT Driving

- Delivers precise gate drive signals to IGBTs for fast and efficient operation.

- Enables high-frequency switching, ensuring stable arc performance and reduced spatter.

- Integrated Protection Mechanisms

- Safeguards against overcurrent, overvoltage, and thermal stress.

- Enhances durability by protecting critical machine components.

- Compact and Lightweight Design

- Optimized for integration into modern inverter welding machines.

- Contributes to the portability of the welding system.

- Real-Time Feedback and Monitoring

- Continuously tracks welding parameters like current and voltage.

- Provides adaptive control to maintain arc stability in varying conditions.

- Energy Efficiency

- Reduces power losses with optimized IGBT switching.

- Increases overall machine efficiency, reducing energy costs.

- Versatility and Compatibility

- Works with a wide range of welding machine types, including MMA and TIG systems.

- Supports diverse welding materials and applications.

- Enhanced Arc Stability

- Ensures a consistent and steady arc for superior weld quality.

Applications

- Inverter Arc Welding Machines

- Core component of compact and energy-efficient inverter-based welding systems.

- TIG Welding Machines

- Used for precise Tungsten Inert Gas (TIG) welding, ideal for intricate tasks and thin materials.

- MMA Welding Machines

- Suitable for heavy-duty Manual Metal Arc (MMA) welding applications.

- Industrial Automation Systems

- Powers automated welding solutions in industrial assembly lines.

- Repairs and Maintenance Services

- Provides flexibility for welding in repair and maintenance tasks across various metal types.

- Custom Welding Applications

- Adaptable to specialized welding needs in industries like shipbuilding, construction, and manufacturing.

SKU: n/a -

Control Card

Single-PCB-IGBT-IC-Control-Card

The single PCB control card for welding machines is a compact and integrated solution that regulates welding processes with precision. It combines various control components onto a single board, simplifying wiring and assembly. Through advanced algorithms, it monitors and adjusts welding parameters in real-time, ensuring consistent weld quality. Versatile and user-friendly, it’s compatible with different welding types and offers efficient operation for industrial and commercial applications.

Features

- Compact design for space-saving installation.

- High-performance microcontroller for precise control over welding parameters.

- Integrated circuitry for monitoring and regulating voltage, current, and temperature.

- User-friendly interface for easy operation and adjustment of welding settings.

- Built-in safety features to prevent overheating, overloading, and short circuits.

- Compatibility with various welding processes and power sources.

- Robust construction for durability and reliability in industrial environments.

- Flexible connectivity options for interfacing with external devices and peripherals.

- Modular design for easy maintenance and upgradeability.

- Advanced control algorithms for optimized welding performance and efficiency.

Applications

- Welding machines for various welding processes such as arc welding, MIG welding, TIG welding, etc.

- Industrial fabrication and manufacturing processes requiring precise control over welding parameters.

- Automotive and aerospace industries for welding components and structures.

- Construction projects for welding structural steel and other metal components.

- Repair and maintenance workshops for welding repairs on machinery, equipment, and vehicles.

SKU: n/a