Shop

Showing 61–75 of 208 results

-

Control Card

200-MOSFET-Control Card(Without Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Control Card

200-MOSFET-Control Card(With Preset)

The “200-MOSFET Control Card” is a vital component in welding machines, responsible for regulating and controlling the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) used in the welding process. These control cards ensure precise modulation of current and voltage, enabling efficient and accurate welding operations. They also provide protection features to safeguard the MOSFETs and other sensitive components from damage due to overcurrent or overheating. Overall, the 200-MOSFET Control Card plays a crucial role in maintaining the stability, reliability, and performance of the welding machine.

Features

- Precise MOSFET Control: Offers precise control over MOSFETs for accurate modulation of current and voltage.

- Smooth Welding Performance: Regulates MOSFET switching behavior to ensure consistent and smooth welding performance.

- Advanced Control Algorithms: Incorporates advanced algorithms to optimize welding parameters based on specific application requirements.

- Protective Features: Includes overcurrent and overvoltage protection, along with thermal management mechanisms for component safeguarding.

- Durability and Robustness: Designed to withstand industrial environments, minimizing downtime and maintenance issues.

- Enhanced Weld Quality: Contributes to improved weld quality by maintaining precise control over welding parameters and performance consistency.

Applications

- Industrial Welding Machines: Used in various industrial welding machines such as arc welders, MIG welders, TIG welders, and plasma cutters.

- Fabrication Workshops: Deployed in fabrication workshops for metalworking processes, including welding, cutting, and joining of metal components.

- Automotive Manufacturing: Employed in automotive manufacturing facilities for welding automotive components and body panels.

- Shipbuilding and Construction: Utilized in shipbuilding yards and construction sites for welding structural components and assemblies.

- Repair and Maintenance: Used in repair and maintenance operations across industries to perform welding tasks efficiently and accurately.

SKU: n/a -

Control Card

4-IGBT-Card-Blank Card

The 4-IGBT-Card Blank Card plays a vital role in the performance and efficiency of modern arc welding machines. It is specifically designed to control the operation of Insulated Gate Bipolar Transistors (IGBTs), which are at the heart of inverter-based welding technology.

Features

- High-Speed IGBT Driving

- Delivers precise gate drive signals to IGBTs for fast and efficient operation.

- Enables high-frequency switching, ensuring stable arc performance and reduced spatter.

- Integrated Protection Mechanisms

- Safeguards against overcurrent, overvoltage, and thermal stress.

- Enhances durability by protecting critical machine components.

- Compact and Lightweight Design

- Optimized for integration into modern inverter welding machines.

- Contributes to the portability of the welding system.

- Real-Time Feedback and Monitoring

- Continuously tracks welding parameters like current and voltage.

- Provides adaptive control to maintain arc stability in varying conditions.

- Energy Efficiency

- Reduces power losses with optimized IGBT switching.

- Increases overall machine efficiency, reducing energy costs.

- Versatility and Compatibility

- Works with a wide range of welding machine types, including MMA and TIG systems.

- Supports diverse welding materials and applications.

- Enhanced Arc Stability

- Ensures a consistent and steady arc for superior weld quality.

Applications

- Inverter Arc Welding Machines

- Core component of compact and energy-efficient inverter-based welding systems.

- TIG Welding Machines

- Used for precise Tungsten Inert Gas (TIG) welding, ideal for intricate tasks and thin materials.

- MMA Welding Machines

- Suitable for heavy-duty Manual Metal Arc (MMA) welding applications.

- Industrial Automation Systems

- Powers automated welding solutions in industrial assembly lines.

- Repairs and Maintenance Services

- Provides flexibility for welding in repair and maintenance tasks across various metal types.

- Custom Welding Applications

- Adaptable to specialized welding needs in industries like shipbuilding, construction, and manufacturing.

SKU: n/a -

Cable Gland

Big-Size-Cable-Gland-J Lock-PG 13.5

The Big-Size Cable Gland J Lock PG 13.5 is a mechanical cable entry device used to secure, seal, and protect electrical cables as they pass through panels, enclosures, or equipment walls. It is particularly vital in industrial and high-current environments like welding machines, where safety, durability, and environmental protection are critical.

Features

-

Thread Size: PG 13.5 standard (~18.5 mm outer diameter)

-

Clamping Range: Typically supports cables from 10 mm to 14 mm in diameter

-

Material: Available in high-quality nylon (PA66) or metal for added durability

-

Lock Nut (J Lock): Ensures secure mounting and resists loosening from vibration

-

Sealing Insert: Provides IP68-rated waterproof and dustproof protection

-

Temperature Resistance: Operates in temperatures from -40°C to +100°C

-

Flame Retardant and UV Resistant: Suitable for harsh industrial conditions

-

Easy Installation: No special tools required – just tighten by hand or with a wrench

-

Corrosion Resistant: Long-lasting performance even in chemically exposed areas

-

Non-Conductive (for nylon types): Ensures electrical insulation around live conductors

Applications

-

Used in welding machines for secure cable entry and strain relief

-

Ideal for high-current power cables and control signal wires

-

Commonly used in industrial electrical panels and enclosures

-

Suitable for dusty, humid, or wet environments where cable sealing is critical

-

Employed in machinery, automation systems, and power distribution boxes

-

Helps maintain IP-rated protection in outdoor or rugged equipment

-

Provides cable support in vibration-prone applications, such as portable welding units

SKU: n/a -

-

Cable Gland

Big-Size-Cable-Gland-J Lock-PG 16

The Big-Size Cable Gland J Lock PG 16 is a mechanical cable entry device used to secure, seal, and protect electrical cables as they pass through panels, enclosures, or equipment walls. It is particularly vital in industrial and high-current environments like welding machines, where safety, durability, and environmental protection are critical.

Features

-

Thread Size: PG 16 standard (~22.5 mm outer diameter)

-

Clamping Range: Typically supports cables from 10 mm to 14 mm in diameter

-

Material: Available in high-quality nylon (PA66) or metal for added durability

-

Lock Nut (J Lock): Ensures secure mounting and resists loosening from vibration

-

Sealing Insert: Provides IP68-rated waterproof and dustproof protection

-

Temperature Resistance: Operates in temperatures from -40°C to +100°C

-

Flame Retardant and UV Resistant: Suitable for harsh industrial conditions

-

Easy Installation: No special tools required – just tighten by hand or with a wrench

-

Corrosion Resistant: Long-lasting performance even in chemically exposed areas

-

Non-Conductive (for nylon types): Ensures electrical insulation around live conductors

Applications

-

Used in welding machines for secure cable entry and strain relief

-

Ideal for high-current power cables and control signal wires

-

Commonly used in industrial electrical panels and enclosures

-

Suitable for dusty, humid, or wet environments where cable sealing is critical

-

Employed in machinery, automation systems, and power distribution boxes

-

Helps maintain IP-rated protection in outdoor or rugged equipment

-

Provides cable support in vibration-prone applications, such as portable welding units

SKU: n/a -

-

POT Wires

Volume Control Connector Wire(POT Wire)

POT connecting wires play a critical role in arc welding machines by ensuring accurate monitoring and real-time display of welding parameters. Their high durability, signal integrity, and resistance to heat make them a vital component in maintaining machine efficiency and safety.

Features

-

High Electrical Conductivity – Ensures efficient signal transmission with minimal resistance.

-

Heat and Flame Resistant – Designed to withstand high temperatures in welding environments.

-

Shielded to Prevent Interference – Reduces electromagnetic interference (EMI) for accurate data display.

-

Durable Insulation – Made from PVC, silicone, or Teflon coatings for longevity.

-

Flexible and Easy to Install – Allows smooth routing inside the welding machine without damage.

Applications

-

Connecting Digital Display Panels – Transmits data between the control board and LCD/LED screens.

-

Signal Transmission for Voltage & Current Monitoring – Ensures real-time display of welding parameters.

-

Linking Control Board to User Interface – Connects keypads, switches, and display modules for machine control.

-

Data Feedback from Sensors – Transfers information from temperature, current, and voltage sensors to the display.

-

Error Code and Warning Display – Sends signals to display fault indicators and system warnings.

-

Power Supply for Display Modules – Provides necessary voltage to LED/LCD screens and indicator lights.

SKU: n/a -

-

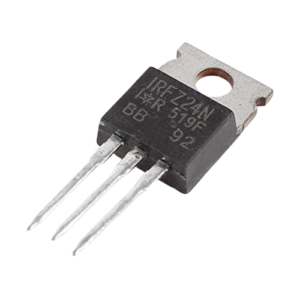

IGBT

50T120

The 50T120 IGBT is a type of Insulated Gate Bipolar Transistor commonly used in welding machines for efficient power switching and control. It combines high-speed switching capabilities with the ability to handle high currents, making it suitable for various welding applications.

Features

• Very low VCE(sat) 1.5 V (typ.)

• Maximum Junction Temperature 175 °C

• Short circuit withstand time – 5µs

• TrenchStop®

and Fieldstop technology for 600 V applications

offers :

– very tight parameter distribution

– high ruggedness, temperature stable behavior

– low VCE(sat)

• Positive temperature coefficient in VCE(sat)

• Low EMI

• Low Gate Charge

• Qualified according to JEDEC for target applications

• Pb-free lead plating; RoHS compliant

• Complete product spectrum and PSpice ModelsApplications

• Inductive Cooking

• Soft Switching ApplicationsSKU: n/a -

Miscellaneous Spare Parts

PVC-MOSFET-Insulating-Strip-Set

The PVC MOSFET Insulating Strip Set is an essential component in arc welding machines, offering electrical insulation, thermal protection, and enhanced reliability. It plays a key role in ensuring safe and efficient operation of welding machines by protecting MOSFETs from electrical faults, heat damage, and environmental stress.

Features

-

High Electrical Insulation – Prevents short circuits and leakage currents in MOSFET circuits.

-

Heat and Flame Resistant – Withstands high temperatures in power electronics applications.

-

Flexible and Durable Material – Made from high-grade PVC for long-lasting performance.

-

Custom Fit for MOSFETs – Designed to cover and protect MOSFET terminals effectively.

-

Chemical and Moisture Resistant – Prevents corrosion and degradation in harsh environments.

Applications

-

MOSFET Insulation – Provides electrical isolation between MOSFETs and the heat sink to prevent short circuits.

-

Thermal Management – Helps in heat dissipation by ensuring proper MOSFET mounting and protection.

-

High-Frequency Welding Inverters – Used in inverter-based arc welding machines for safe MOSFET operation.

-

Circuit Board Protection – Shields sensitive electronic components from unintended electrical contact.

-

Voltage Regulation Circuits – Ensures stable operation of MOSFETs in power supply and control modules.

-

Prevention of Electrical Arcing – Reduces the risk of high-voltage arcing in welding machine circuits.

SKU: n/a -

-

Supply Card

24 Volt Supply Card-Small Card with Relay

The 24 Volt Supply Card-Small Card with Relay is an essential component in many modern welding machines, especially those with sophisticated control systems. It provides a stable 24V DC output from the main power supply, ensuring that various low-power electronic systems within the welding machine operate efficiently and reliably.

This card plays a crucial role in supplying power to internal components such as control boards, sensors, displays, and communication interfaces. The 24V supply is vital for powering these auxiliary systems without interfering with the machine’s main high-power welding operations.

Features

- Stable 24V DC Output: Provides a reliable 24V power source for the welding machine’s control systems, sensors, and auxiliary components.

- Power Conversion Efficiency: Converts high-voltage input into a stable 24V output, ensuring reliable operation of low-voltage components.

- Compact and Space-Efficient Design: Designed to fit within compact welding machine enclosures, optimizing internal space.

- Durability: Built to endure harsh industrial conditions, including heat, dust, and vibrations, ensuring long-term operation.

- Overload and Short-Circuit Protection: Includes protection features to safeguard internal components from power surges or failures.

- High Efficiency: Low power consumption and minimal heat generation during operation.

- Thermal Management: Equipped with cooling mechanisms to maintain optimal performance and prevent overheating.

- User-Friendly Integration: Easy to integrate into various welding machine models, compatible with multiple configurations.

- plications

SKU: n/a -

Control Card

MMA-400-Control Card-T2

The MMA-400 Control Card is an essential element in the operation of 3-phase arc welding machines, specifically engineered to provide precise control over the welding process. Its design emphasizes high efficiency and reliability, making it an ideal choice for use in demanding industrial environments where consistent performance is critical.

At the core of its functionality is advanced IGBT (Insulated Gate Bipolar Transistor) technology, which serves as a robust solution for managing high-power operations. This technology combines the efficiency of MOSFETs with the power-handling capability of BJTs, allowing the MMA-400 Control Card to regulate and deliver high current outputs with minimal energy loss.

This capability ensures smooth and stable welding arcs, a key factor in achieving superior weld quality. The card is adept at managing fluctuations in power supply, ensuring that the welding machine operates consistently even under challenging conditions. Its ability to handle high currents makes it particularly suitable for heavy-duty applications such as structural welding, shipbuilding, and industrial fabrication.

In addition to its performance capabilities, the MMA-400 Control Card is built with durability in mind. Its rugged construction allows it to withstand harsh environmental conditions, including high temperatures, dust, and moisture, common in industrial settings. These features collectively make it a reliable and efficient component in 3-phase arc welding machines, ensuring both productivity and operational safety.

Features

- Three-Phase Power Support: Operates seamlessly with 3-phase power supply for higher efficiency and reduced energy consumption.

- High Current Capability: Handles output currents up to 400A, suitable for heavy-duty applications.

- IGBT Technology: Offers efficient energy management, stable performance, and minimal heat generation.

- Accurate Current Control: Regulates current flow for consistent welding arcs and superior weld quality.

- Safety Mechanisms: Includes protection against overcurrent, short circuits, overvoltage, and overheating.

- Durable Design: Built to withstand industrial wear and tear, with robust materials for long-term use.

- Thermal Management: Equipped with advanced cooling features to maintain performance during extended operations.

- Configurable Settings: Adjustable parameters to meet various welding requirements.

Applications

- Construction: Ideal for structural welding in buildings and infrastructure projects.

- Manufacturing: Essential for fabricating heavy machinery and industrial equipment.

- Automotive: Widely used in the production and repair of automotive parts.

- Shipbuilding: Suitable for welding large-scale metal structures in shipyards.

- Pipeline Welding: Handles high-current welding for industrial and oil pipeline projects.

- Custom Fabrication: Perfect for workshops and fabrication units catering to diverse welding tasks.

SKU: n/a -

Bridge Wires

Bridge-Wires

Bridge connecting wires play a critical role in arc welding machines by ensuring accurate monitoring and real-time display of welding parameters. Their high durability, signal integrity, and resistance to heat make them a vital component in maintaining machine efficiency and safety.

Features

-

High Electrical Conductivity – Ensures efficient signal transmission with minimal resistance.

-

Heat and Flame Resistant – Designed to withstand high temperatures in welding environments.

-

Shielded to Prevent Interference – Reduces electromagnetic interference (EMI) for accurate data display.

-

Durable Insulation – Made from PVC, silicone, or Teflon coatings for longevity.

-

Flexible and Easy to Install – Allows smooth routing inside the welding machine without damage.

Applications

-

Connecting Digital Display Panels – Transmits data between the control board and LCD/LED screens.

-

Signal Transmission for Voltage & Current Monitoring – Ensures real-time display of welding parameters.

-

Linking Control Board to User Interface – Connects keypads, switches, and display modules for machine control.

-

Data Feedback from Sensors – Transfers information from temperature, current, and voltage sensors to the display.

-

Error Code and Warning Display – Sends signals to display fault indicators and system warnings.

-

Power Supply for Display Modules – Provides necessary voltage to LED/LCD screens and indicator lights.

SKU: n/a -

-

Capacitor Wires

Capacitor-Wires

Capacitor connecting wires play a critical role in arc welding machines by ensuring accurate monitoring and real-time display of welding parameters. Their high durability, signal integrity, and resistance to heat make them a vital component in maintaining machine efficiency and safety.

Features

-

High Electrical Conductivity – Ensures efficient signal transmission with minimal resistance.

-

Heat and Flame Resistant – Designed to withstand high temperatures in welding environments.

-

Shielded to Prevent Interference – Reduces electromagnetic interference (EMI) for accurate data display.

-

Durable Insulation – Made from PVC, silicone, or Teflon coatings for longevity.

-

Flexible and Easy to Install – Allows smooth routing inside the welding machine without damage.

Applications

-

Connecting Digital Display Panels – Transmits data between the control board and LCD/LED screens.

-

Signal Transmission for Voltage & Current Monitoring – Ensures real-time display of welding parameters.

-

Linking Control Board to User Interface – Connects keypads, switches, and display modules for machine control.

-

Data Feedback from Sensors – Transfers information from temperature, current, and voltage sensors to the display.

-

Error Code and Warning Display – Sends signals to display fault indicators and system warnings.

-

Power Supply for Display Modules – Provides necessary voltage to LED/LCD screens and indicator lights.

SKU: n/a -

-

Display Wires

Display-Wire

Display connecting wires play a critical role in arc welding machines by ensuring accurate monitoring and real-time display of welding parameters. Their high durability, signal integrity, and resistance to heat make them a vital component in maintaining machine efficiency and safety.

Features

-

High Electrical Conductivity – Ensures efficient signal transmission with minimal resistance.

-

Heat and Flame Resistant – Designed to withstand high temperatures in welding environments.

-

Shielded to Prevent Interference – Reduces electromagnetic interference (EMI) for accurate data display.

-

Durable Insulation – Made from PVC, silicone, or Teflon coatings for longevity.

-

Flexible and Easy to Install – Allows smooth routing inside the welding machine without damage.

Applications

-

Connecting Digital Display Panels – Transmits data between the control board and LCD/LED screens.

-

Signal Transmission for Voltage & Current Monitoring – Ensures real-time display of welding parameters.

-

Linking Control Board to User Interface – Connects keypads, switches, and display modules for machine control.

-

Data Feedback from Sensors – Transfers information from temperature, current, and voltage sensors to the display.

-

Error Code and Warning Display – Sends signals to display fault indicators and system warnings.

-

Power Supply for Display Modules – Provides necessary voltage to LED/LCD screens and indicator lights.

SKU: n/a -

-

Pin Connectors

7Pin-Connector

The 7-pin connector plays a crucial role in welding machines by ensuring stable power, signal, and control connections. Its robust and high-performance design enhances the efficiency, reliability, and safety of welding operations, making it an indispensable component in industrial and professional welding applications.

Features

-

High Durability – Built with heat-resistant and impact-resistant materials to withstand harsh industrial environments.

-

Secure Locking Mechanism – Prevents accidental disconnections, ensuring uninterrupted operation.

-

High Current and Voltage Handling – Supports stable power transmission for welding controls.

-

Electromagnetic Shielding – Reduces interference (EMI) for consistent signal communication.

-

Compact and Modular Design – Easily integrates into various welding machine configurations.

-

Corrosion-Resistant Contacts – Ensures long-lasting performance even in high-temperature conditions.

Applications

-

Power Distribution

-

Transfers power between control boards, torches, and accessories.

-

Ensures efficient energy flow for stable welding operations.

-

-

Control Signal Transmission

-

Connects the welding control panel to internal circuits.

-

Allows users to adjust welding parameters (current, voltage, arc force, etc.).

-

-

Foot Pedal and Remote Control Interface

-

Enables hands-free operation using a foot pedal or remote controller.

-

Enhances precision control over welding power.

-

-

Torch and Electrode Holder Connectivity

-

Links the welding torch or electrode holder to the power supply.

-

Ensures a stable and efficient current flow for arc formation.

-

-

Cooling System Integration

-

Connects to cooling fans or water-cooled torches for heat dissipation.

-

Prevents overheating and prolongs welding machine lifespan.

-

-

Data and Feedback Communication

-

Facilitates real-time monitoring of welding parameters.

-

Integrates with advanced digital control and automation systems.

-

SKU: n/a -